Upgrade

Your System 2.0

Everything you need to know about updating an earlier generation System 2.0 to current performance, safety and control standards.

Why upgrading makes sense

Earlier installations may still operate reliably, but they were built for a different time. More than 10 years of real-world experience have shaped today’s precision-engineered System 2.0, designed for dependable operation in the years ahead.

Reduced service complexity

Standardized components ensure spare-part availability and continued support. Up-to-date control systems and software enable remote service and efficient system diagnostics.

Long-term operational reliability

All components are designed for optimized wear behavior and a defined service life, supporting safe operation, efficient maintenance and predictable service intervals.

Improved ride quality

The counterweight unit stabilizes cable behavior and maintains a consistent pull, resulting in a controlled and comfortable riding experience across all skill levels.

HERE IS

How it Works

Step 1: Compatibility check

We inspect your existing System 2.0 to verify suitability and define the exact scope of the upgrade.

Step 2: Delivery

All required components are delivered directly to your site on Euro pallets.

Step 3: Installation

The upgrade is carried out on site by our technician together with your team and typically takes around two days.

Step 4: Commissioning

The System is set up, tested and handed over, including operator briefing.

Step 5: Back in operation

Downtime is usually limited to the installation period only.

Frequently Asked Questions about the Upgrade

The Upgrade Kit is designed for System 2.0 installations built between 2008 and 2019. During an initial technical assessment, we check the condition of the existing System to confirm compatibility and define the exact scope of the upgrade.

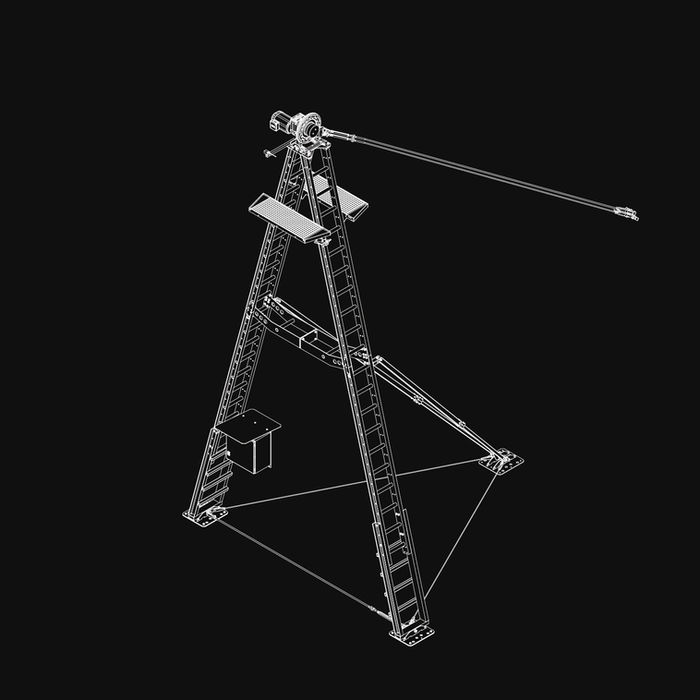

All critical mechanical, electrical and control components are replaced with current technology. In practice, almost everything is renewed – except the existing towers, which remain in place.

No. The Upgrade Kit is designed as an integrated solution. Partial upgrades are not possible, as mixing old and new components can reduce reliability and lead to compatibility issues.

No. The tension weight unit is designed as an integral part of the complete upgrade and cannot be retrofitted to older heads, as they are not structurally designed to carry the required loads.

Technically possible, but strongly not recommended, as control cabinets and frequency inverters typically have a service life of around 10 years and may fail unexpectedly, compromising long-term reliability.

There are no fixed limits. Each installation is assessed individually before the upgrade.

No. All upgrades are carried out exclusively by our team, as trained and experienced technicians are essential to ensure safe and reliable installation and operation.

No. The System 2.0 must be taken out of operation during the installation. We recommend planning the upgrade outside peak operation periods.

Yes. After installation, our technician will brief your team on operation, safety and basic maintenance.

Yes. The Upgrade Kit brings the installation in line with current System 2.0 safety and technical standards.

No. The existing towers remain in place and no foundation work is required, provided the current installation is structurally sound.

Yes. Additional service work or adjustments can be coordinated as part of the upgrade and discussed during the initial assessment.

All removed components (e.g. heads, motors and control components) are retained by us. This helps ensure that outdated parts are not resold or reinstalled elsewhere.

Meet our Core-Team

Sebi Suess

CEO

Lukas Suess

Sales & Marketing

Michi Markus

Electric Controls

Henri Dollenberg

Head Technician